What Are Wood Screws?

Wood screws are a staple in both DIY and professional woodworking projects, embodying the essence of joining and crafting with wood. At their core, wood screws are fasteners designed specifically for the task of piecing together pieces of wood, offering a durable and reliable bond that can withstand the test of time and usage. Unlike regular steel screws or drywall screws, the best wood screws come with features like coarse threads for better grip in wooden substrates, a sharp point for easy insertion, and a variety of head styles to suit different applications and aesthetics. From flat head screws for a flush finish to truss head screws for a broader bearing surface, understanding what are wood screws and their functionalities is paramount for any woodworking project.

Top Factors to Consider When Selecting Wood Screws

Selecting the right screw for your woodworking project is not as straightforward as it might seem. The key factors include the material (stainless steel screws offer corrosion resistance while solid brass screws bring a decorative finish), the screw head and drive type (Phillips head screws, square drive, or Torx head for better torque), and the length and gauge for the right strength and fit. Furthermore, considering whether your project is for interior diy projects or exterior use can dictate the need for specialized features like a dual barrier coating system for greater protection against the elements. Another crucial aspect is the thread type; fine threads are typically better for hardwoods to prevent splitting, whereas coarse threads are ideal for softwood or particle board for a stronger grip.

In addition to these considerations, the application of the screw plays a pivotal role in your selection process. For instance, if you are working on projects that require the assembly and disassembly of parts, such as in furniture making or temporary constructions, you might opt for screws with features that facilitate this process, like trim head screws for a discreet look or pan head screws for easy access and adjustment. The choice between self-tapping screws and traditional wood screws will also depend on the materials you are working with and whether you prefer the convenience of not having to pre-drill pilot holes.

Moreover, the environmental conditions your project will face cannot be overlooked. For outdoor projects or those exposed to moist environments, choosing screws with corrosion-resistant materials and coatings, such as stainless steel or silicon bronze screws, becomes imperative. These materials ensure that your project retains its integrity and appearance over time, resisting the corrosive effects of weather and moisture. Similarly, if your project involves treated lumber, it’s crucial to select screws, like stainless steel or specially coated screws, that are compatible with the chemicals used in the wood treatment process to avoid corrosion and ensure the longevity of both the screws and the wood.

6 Best Wood Screws Recommended for Your DIY Project

#1 High-Performance Cam Screw for Wood

The High-Performance Cam Screw tops our list as the best wood screw for a variety of woodworking projects, thanks to its innovative design that combines ease of use with unmatched stability. Engineered for exceptional grip, these screws feature a unique cam mechanism that ensures a tight fit without the risk of damaging the wood during installation. This makes them equally suited for delicate hardwoods and resilient softwoods. Their corrosion-resistant coating further enhances their versatility, allowing them to be used in both indoor and outdoor settings without fear of wear or rust. For professionals and hobbyists who demand the best in their fastening solutions, these high-performance cam screws are the go-to choice for projects that require both durability and precision.

#2 Budget-Friendly Particle Board Screws

Particle Board Screws present a cost-effective solution for DIYers and professionals alike, striking an excellent balance between affordability and reliable performance. These screws are specifically designed to cater to the needs of softer materials like particle board, featuring coarse threads that ensure a solid grip without causing material split. This makes them particularly useful for furniture assembly and other interior projects where budget constraints are a consideration without compromising the overall quality of the work. Their durability and affordability make Particle Board Screws an ideal selection for those seeking to complete their projects on a budget while still achieving professional-grade results.

#3 Zinc-Coating Cam Lock Screws for Outdoor Use

Zinc-Coating Cam Lock Screws stand out for their exceptional durability and resistance to environmental wear, making them ideal for outdoor woodworking projects. The protective zinc coating acts as a barrier against corrosion, extending the life of your projects even in the most challenging outdoor conditions. The cam lock mechanism provides a secure, vibration-resistant hold, ensuring structures like decks and outdoor furniture remain stable and intact over time. These screws are designed to withstand the elements, offering builders and DIY enthusiasts a reliable fastening solution for any project exposed to outdoor environments.

#4 Specialty Wood Screws for Fine Woodworking

Specialty Wood Screws are crafted for projects that require a high level of precision and aesthetic consideration, such as fine furniture making and cabinetry. These screws are available in a variety of sizes and finishes, including an attractive yellow-zinc coating that not only provides corrosion resistance but also blends seamlessly with a range of wood types. The small head design allows for a subtle appearance, ensuring the focus remains on the craftsmanship of your work rather than the fasteners. Their sharp point and precise threading facilitate easy insertion and a secure hold, making them the ideal choice for woodworkers who prioritize both strength and beauty in their projects.

#5 The Best Confirmat Screws for Strength and Durability

Confirmat Screws are specifically engineered for assembling robust and durable furniture, offering unparalleled strength and ease of use. These screws are uniquely designed to create a tight and secure connection between panels, eliminating the need for complex joinery techniques. This simplifies the assembly process while ensuring that the final construction is both sturdy and reliable. Ideal for heavy-duty furniture such as bookshelves and cabinets, Confirmat Screws are the top choice for anyone looking to combine efficiency with durability in their woodworking projects.

#6 Eco-Friendly Wood Screws: Sustainable Choices

Eco-Friendly Wood Screws embody the shift towards sustainable building materials, offering a responsible choice for environmentally conscious woodworkers. Made from either recycled materials or sustainably sourced woods, these screws provide a green alternative to traditional fasteners without compromising on performance. They cater to the growing demand for sustainable construction practices, allowing builders to minimize their environmental footprint while still delivering durable and aesthetically pleasing results. For projects where sustainability is as important as quality, eco-friendly wood screws are the ideal choice, ensuring that your work is both environmentally responsible and built to last.

How to Ensure the Perfect Wood Screw Size?

Ensuring the perfect wood screw size is crucial for the integrity of your woodworking project. The length of the screw should be chosen based on the thickness of the materials being joined; a general rule is that the screw should penetrate at least half the thickness of the bottom material. Additionally, the gauge or diameter of the screw affects its strength and the size of the pilot hole needed. Using a drill bit slightly smaller than the diameter of the screw shank ensures a tight fit without splitting the wood. Remember, the right size not only guarantees a secure hold but also preserves the aesthetics of your project. Whether you’re working with treated lumber for outdoor applications or delicate hardwoods for fine furniture, selecting the appropriate screw size is a step that cannot be overlooked.

To further refine your selection, consider the head style and drive type in relation to the tooling you have available and the finish you desire. For projects where the screw heads may be visible, choosing a screw with a decorative finish, such as brass or stainless steel screws, can enhance the overall look. For instance, trim head screws offer a minimalistic appearance, blending seamlessly with the wood, while washer head screws provide a larger bearing surface, ideal for attaching hardware or mounting items where additional holding power is needed.

Additionally, understanding the specific requirements of your project can lead to more nuanced choices, such as opting for specialized screws like pocket screws for creating strong, hidden joints in furniture, or using self-tapping screws to simplify processes in metal-to-wood connections. It’s also worthwhile to consider the environmental impact of your project. Eco-friendly wood screws, made from sustainable materials or designed for easy disassembly and recycling, can contribute to a greener build. By considering these factors in conjunction with the basic guidelines on length and gauge, you can ensure that the screws you select will not only hold your project together effectively but also contribute to its functionality, durability, and aesthetic appeal.

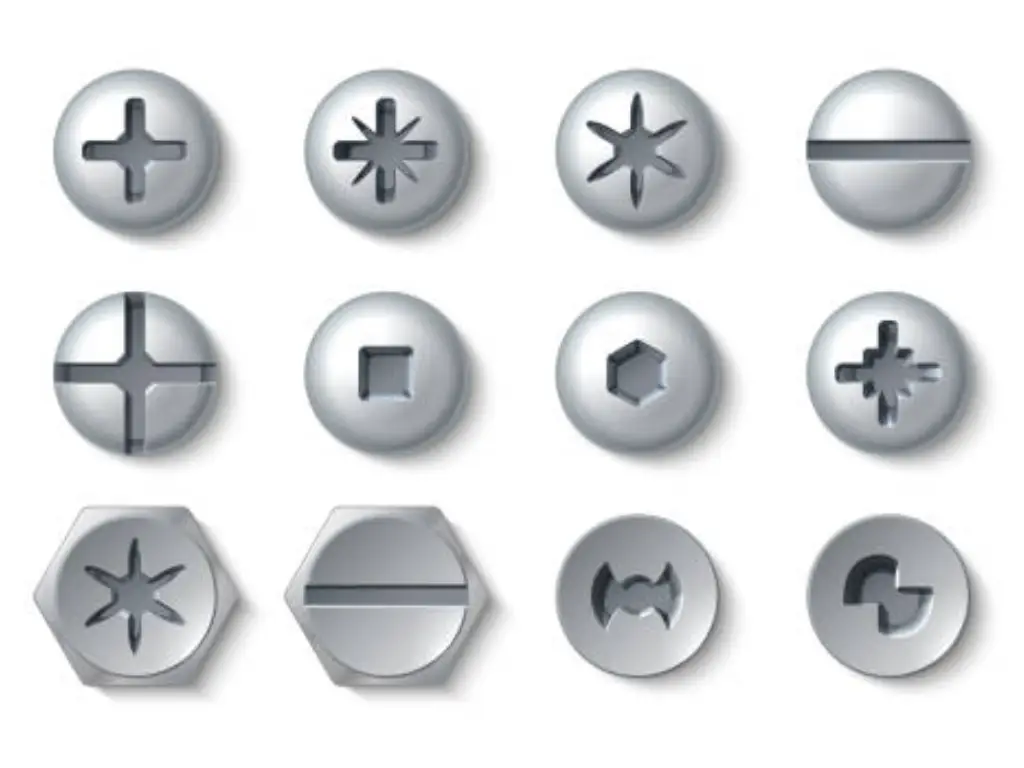

Different Types of Wood Screws Head and Drive Styles

The head and drive styles of wood screws play a significant role in the functionality and finish of your project. From flat head screws that provide a smooth, flush finish to round head screws that offer a decorative look, the choice of head style should align with your project’s aesthetic and structural requirements. Adding to the variety, washer head screws offer increased surface area, making them ideal for securing hardware where additional hold is needed, such as with drawer slides or in some types of construction screws. Trim head screws, on the other hand, feature a smaller head that allows them to disappear into the surface of the wood, perfect for a clean, minimalistic look.

Drive types such as Phillips, square, and Torx offer varying degrees of torque control and cam-out resistance. For instance, Torx head screws are renowned for their superior hold and ease of driving, making them a preferred choice for high-torque applications. Square head screws provide a reliable connection with less risk of strip-out, which is especially beneficial in applications requiring disassembly and reassembly. Pan head screws have a flat bottom and rounded top, offering a compromise between holding power and aesthetics, making them versatile for a variety of applications.

The advent of specialized screws such as self-tapping screws, which can create their own thread as they are driven into wood, metal, or other materials, further expands the toolbox of the modern woodworker. These screws are particularly useful in situations where pre-drilling a pilot hole is not feasible or where the material’s integrity must be preserved as much as possible.

Moreover, the introduction of pocket screws has revolutionized joinery, especially in cabinet making and furniture construction. These screws are designed for use with a special jig, allowing for strong, hidden joints that are both aesthetically pleasing and structurally sound. The use of production screws in manufacturing settings, where efficiency and reliability are paramount, showcases the importance of selecting the right screw for the job.

Understanding the differences between these options will enable you to make informed decisions that enhance the quality and durability of your woodworking endeavors. Whether you’re assembling a delicate piece of furniture or constructing a robust outdoor deck, the correct choice of wood screw head and drive style can make all the difference in the success of your project.

Pre-drilling Holes for Wood Screws: Necessary Steps

Pre-drilling holes for wood screws is an essential step to prevent splitting, especially when working near the edge of a board or with hardwoods. The pilot hole should be slightly smaller than the screw’s diameter, allowing the threads to cut into the wood and secure a tight fit. For optimal results, use a drill bit that matches the inner diameter of the screw’s threads. Additionally, consider countersinking the small hole if using flat head screws to ensure a flush finish. This preparatory step not only facilitates easier screw insertion but also significantly enhances the overall strength and appearance of your project.

Beyond preventing wood splitting, pre-drilling also ensures that the screw aligns correctly with the workpieces. Misalignment can lead to weaker joints and an unsightly finish. By taking the time to measure and mark where each screw should go, then pre-drilling to the correct depth and diameter, you ensure that each screw contributes to the structural integrity and visual appeal of your project. The effort put into this step pays off in the durability and quality of your finished work.

Common Mistakes to Avoid When Using Wood Screws

One common mistake when using wood screws is neglecting to choose the right type of screw for the material. For example, using regular steel wood screws instead of stainless steel or silicon bronze screws for outdoor applications can lead to corrosion and failure of the joint. Over-tightening is another issue, which can strip the screw hole or crack the wood. Additionally, using a screw that’s too long or too short can compromise the integrity of the joint. Avoid these pitfalls by carefully planning and selecting the appropriate screws for your specific needs, ensuring a successful and durable woodworking project.

Another frequent oversight is ignoring the wood’s grain direction and density. Screws driven perpendicular to the grain or into very dense wood without the proper pilot hole can cause the wood to split, weakening the joint. Furthermore, failing to account for the expansion and contraction of wood in different climates can result in screws becoming loose over time. Choosing the correct screws for the wood type and environment, such as coated screws for moisture resistance, and allowing for wood movement in your design, are critical steps in achieving lasting results with your woodworking projects.

Comparing Wood Screws: Coated vs. Uncoated Options

When comparing coated versus uncoated wood screws, it’s important to consider the environment in which your project will be located. Coated screws, such as those with a zinc or dual barrier coating, offer enhanced corrosion resistance, making them ideal for outdoor or humid environments. On the other hand, uncoated screws, like solid brass or stainless steel, provide a natural resistance to corrosion and can be used where a decorative finish is desired. Each option has its advantages, and the choice should be based on the specific requirements of your project, including exposure to elements and aesthetic considerations.

Here’s a table to help summarize the key differences:

| Feature | Coated Wood Screws | Uncoated Wood Screws |

| Corrosion Resistance | High (zinc or dual barrier coating) | Moderate to High (depends on material, e.g., stainless steel or brass) |

| Ideal Environment | Outdoor or humid environments | Indoor or where corrosion is less of a concern |

| Aesthetic | Typically less decorative, might require hidden installation | Often more decorative, suitable for visible areas |

| Cost | Generally more cost-effective due to additional coating process | Can be more expensive, especially for premium materials like stainless steel or brass |

| Usage | Decks, outdoor furniture, areas prone to moisture | Indoor furniture, decorative applications, areas with moderate moisture exposure |

This table aims to provide a quick reference for deciding between coated and uncoated wood screws based on the specific needs of your project. Whether durability in harsh conditions or aesthetic appeal in interior designs is your priority, understanding these distinctions can guide your selection process towards the most appropriate choice.

Tips for Working with Softwoods and Hardwoods

Working with different types of wood requires adjustments in your approach, especially when it comes to screw selection and installation. Softwoods, being less dense, are more forgiving and can often be worked with using coarser threads and longer screws. This allows for easier penetration and a solid hold without exerting too much pressure that could split the wood. On the other hand, hardwoods, with their denser and more brittle nature, demand finer threads to prevent splitting and may require pre-drilling to facilitate screw insertion. The choice between using a standard wood screw or specialized options like trim head screws for a more aesthetic finish or heavy-duty construction screws for structural projects is crucial in achieving the desired outcome.

Furthermore, the wood’s density and grain pattern play a significant role in selecting the appropriate fastening method. For example, softwoods with a loose grain structure may benefit from screws with a larger thread pitch, which can engage more material for a stronger hold. In contrast, hardwoods with a tight grain structure necessitate screws with a smaller thread pitch and possibly a shank that is smoother near the head to prevent the wood from cracking. Paying attention to these details and choosing screws designed for specific wood types, such as specialized hardwood screws, can significantly impact the success of your project, ensuring a durable and aesthetically pleasing assembly.

The Impact of Thread Design on Wood Screw Performance

The design of a wood screw’s thread significantly impacts its performance. Coarse threads are ideal for softwood, as they provide a stronger grip in the less dense material, making them less likely to strip out when driven. This design feature allows for rapid driving and a secure hold, which is particularly beneficial for construction projects involving pine, cedar, or spruce. Fine threads, on the other hand, are better suited for hardwoods, offering a tighter hold without the risk of splitting. The increased thread count of fine-threaded screws engages more surface area within the denser wood, creating a stronger bond that is essential for furniture making and cabinetry involving oak, maple, or walnut.

Moreover, some screws are designed with dual-thread patterns, combining both coarse and fine threads to maximize grip strength in various materials. This innovative design caters to applications that require versatility, such as in projects that involve both softwood and hardwood components. The dual-thread design ensures that the screw can be used effectively across a wide range of wood types, reducing the need for multiple screw types on a single project. Understanding how thread design affects screw performance is critical for woodworkers and contractors alike, as it enables the selection of the most appropriate screw type for the material at hand, ultimately influencing the project’s overall quality and longevity.

Conclusion

Selecting the best wood screws for your woodworking project is more than just picking up a pack from your local hardware store. It requires understanding the intricacies of wood types, screw materials, head and drive styles, and the specific demands of your project. By considering the factors outlined in this guide, you can ensure that your woodworking projects are not only aesthetically pleasing but also structurally sound and durable. Whether you’re a seasoned woodworker or embarking on your first DIY project, the right wood screws are essential to achieving the best possible results.