The humble hinge, often overlooked, is a critical component in countless applications, from the doors that grant us passage to the cabinets that organize our lives. It is the silent pivot point, the enabling mechanism that allows for movement and access. Understanding the intricacies of hinge parts, the diverse types of hinges available, and the materials that dictate their performance is essential for anyone involved in construction, furniture making, or even simple home repairs. This guide serves to explain the hinge world by offering complete information that enables you to select the right products for your particular requirements.

Understanding the Core Components of Hinge Parts

Hinges serve as basic mechanical connectors which join two solid objects through a rotational motion. A basic hinge operation depends on multiple components which must work together harmoniously.

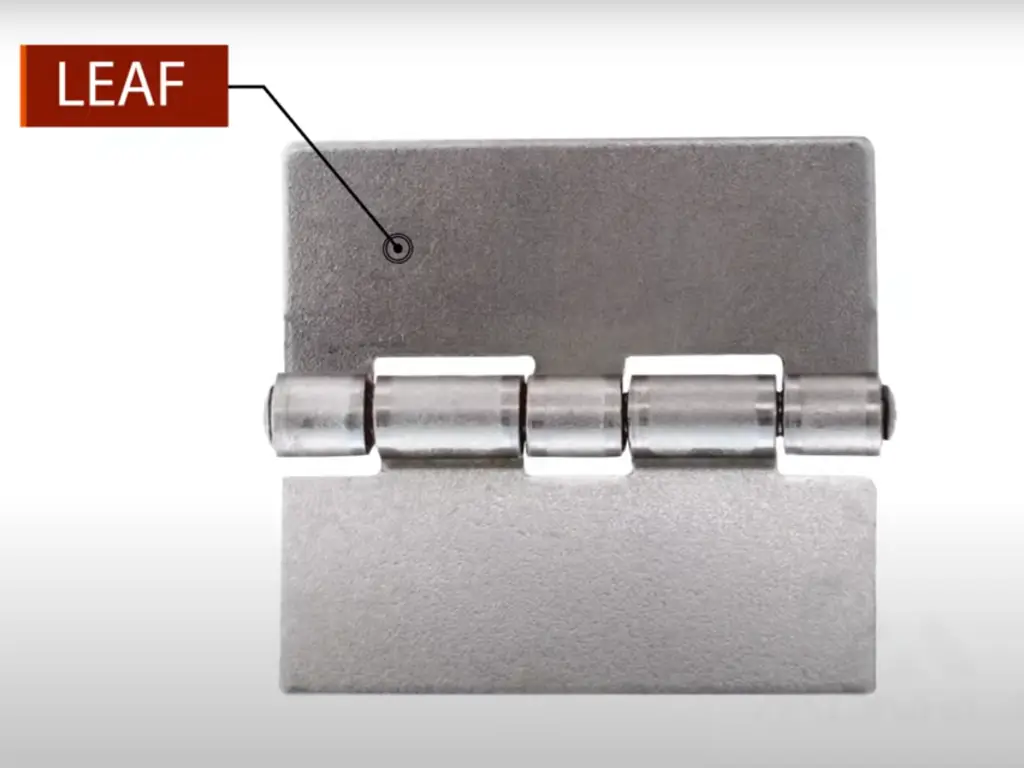

- Leaf : The leaf represents the flat extended part which connects to both objects that need to be joined. The leaf has rectangular shape with screw holes that enable secure attachment. The dimensions of the leaf hinge components depend on the hinge type and required load capacity. Heavy doors and cabinets require wider or longer leaf extensions because they enhance both surface area and structural stability. Specialized hinge designs include single leaf configurations and unique leaf shapes that meet specific application requirements. The leaf functions as the primary component which establishes the base for the entire hinge system to work within door hinge parts.

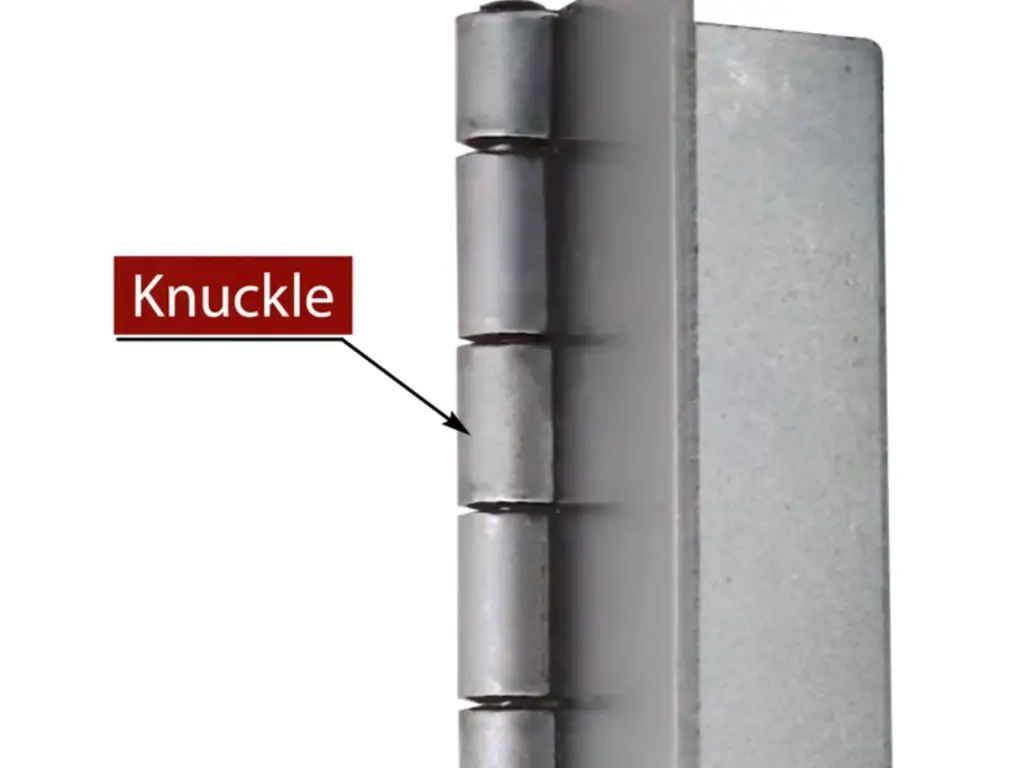

- Knuckle : The knuckle which is also known as a loop or node exists as a cylindrical or conical structure at leaf intersections. The knuckles create a continuous sleeve structure by connecting to each other. The hinge design determines the number of knuckles which form the structure. The pivot joint of the hinge emerges from the knuckles which function as its basic structural component. The rolled sections of leaves create the knuckles which function as parts of the hinge mechanism.

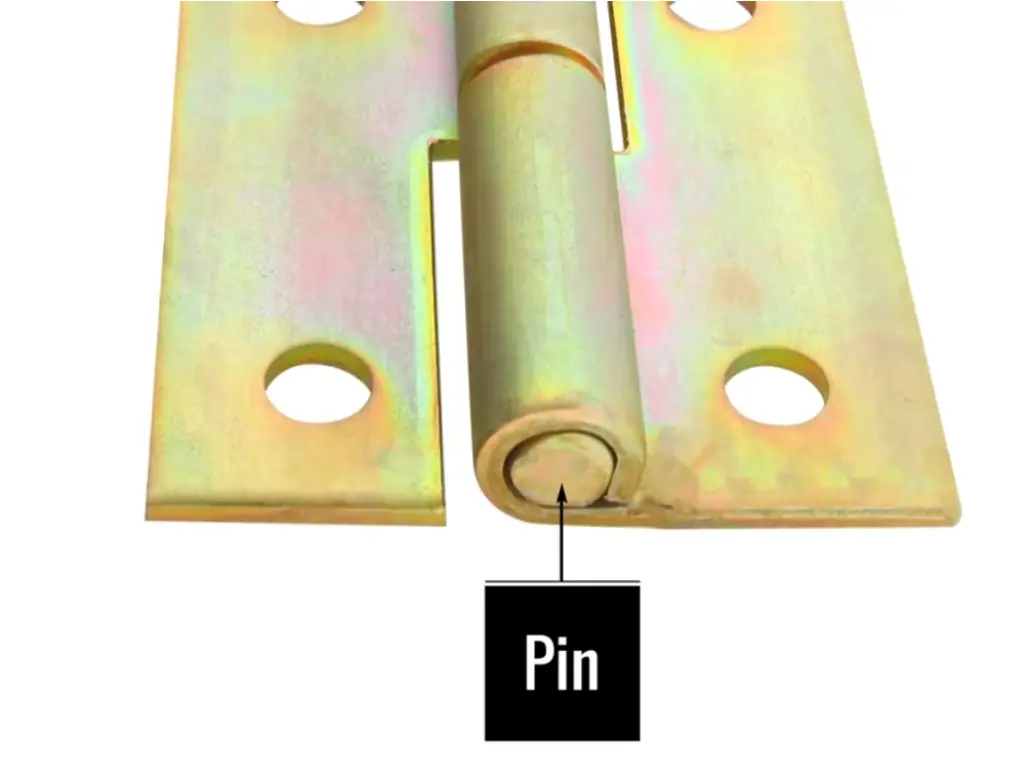

- Pin : The pin functions as a cylindrical rod which travels through properly aligned leaf knuckles to create a connection that enables rotational movement. The hinge pin consists of steel metal which receives precise machining to create a tight fit inside knuckle structures. The pin functions as the rotational center point for leaf movement. The material selection and diameter measurement determine how strong and durable a hinge becomes particularly when facing heavy loads. The hinge includes detachable pins together with pins that remain permanently in place.

The initial step to understand hinge options requires knowledge of their fundamental components. The different hinge designs use these components in distinct arrangements to perform their intended functions.

Exploring Different Hinge Types and Their Unique Parts

This section will delve into various common types of hinges, detailing their unique parts and design features, and how these characteristics determine their applications in different scenarios.

Butt Hinges

Butt hinges represent the fundamental and widespread hinge design among all hinge types. The hinge consists of two rectangular metal leaves which are connected by a pin. The leaf component contains multiple pre-existing holes which allow users to secure it between objects using screws. The pin functions as the hinge’s center point to enable leaf movement between the two parts.

- Unique parts and design features: The simple structure together with low cost and easy installation make this hinge unique.

- Applications: The hinge serves multiple purposes in doorways and windows alongside cabinets and other items that need basic opening and closing operations. The thickness of leaves and pin diameter can change according to the required load capacity.

Strap Hinges

Strap hinges feature leaves that extend into longer straps or strips that exceed the dimensions of butt hinge leaves. The design creates a bigger connection point that delivers enhanced support.

- Unique parts and design features: Slender strap-like leaves that provide stronger support and a larger angle of rotation. Sometimes, decorative patterns are designed on the leaves.

- Applications: Barn doors and gates and trunk lids and various other applications that need strong support and wide rotational range utilize this product. These components find decorative use because of their traditional appearance.

T Hinges

T hinges consist of two leaves where a longer leaf connects to a stationary structure and a perpendicular shorter leaf connects to the moving part. The stationary structure receives the long leaf while the moving part gets the shorter leaf.

- Unique parts and design features: The “T” shape design features stable fixation through the long leaf while connecting the moving part through the short leaf.

- Applications: These hinges work best when used to link lightweight doors or panels to heavier frames such as garden gates and shed doors.

Piano Hinges (Continuous Hinges)

The continuous hinge known as a piano hinge extends throughout the entire length of the connected components. These hinges include two extended thin leaves connected by a single running pin from end to end.

- Unique parts and design features: The hinge design features two extended leaves which support each other through an entire length pin that enables balanced movement.

- Applications: The continuous hinge finds its main use in piano lids and toolbox lids and folding tables and other objects that need support and complete length rotation. The extended and solid construction makes these components able to handle repeated opening and closing operations.

Barrel Hinges

Two cylindrical parts linked through a pin form barrel hinges. The installation process requires drilling holes into the connected objects before inserting the barrel hinge into these openings which results in complete hiding of the hinge when the objects close.

- Unique parts and design features: Cylindrical appearance, good concealment after installation, and compact structure.

- Applications: Suitable for applications where the hinge needs to be hidden, such as jewelry boxes and small cabinet doors. Their small design also makes them popular in space-limited applications.

Concealed Hinges (Invisible Hinges)

Concealed hinges achieve their design objective through complete hiding of all hinge components during the closed state of doors or covers. Complex multiple components within this hinge structure allow for effortless opening and closing movements.

- Unique parts and design features: The complex design of these hinges becomes invisible after installation which results in a clean and sophisticated appearance.

- Applications: This type of hinge serves modern furniture and high-end cabinets alongside various applications that need sophisticated aesthetics. Their concealed nature elevates the overall design quality of products.

Flag Hinges

Flag hinges function through two parts which form a flag shape where one section contains a pin and the other section contains a matching hole. The flag hinge serves applications which need fast assembly or disassembly procedures.

- Unique parts and design features: The flag-shaped design enables fast detachment and reconnection of these parts. The hinge enables movement through a single rotational direction.

- Applications: These hinges serve door panels which need regular removal as well as equipment access panels among other applications. These hinges provide easy disassembly capabilities which makes them ideal for industrial and commercial uses.

Friction Hinges (Torque Hinges)

Friction hinges produce controlled friction effects while rotating, which is their main design characteristic. The built-in friction mechanism enables the door or cover to stay in any desired position without self-closing or self-opening.

- Unique parts and design features: The hinge features a friction mechanism inside which controls rotational damping force adjustment.

- Applications: These applications include laptop screens and adjustable monitor stands and cabinet doors that require open positions. Their friction provides stable positioning.

The various hinge types use basic components such as leaves and knuckles and pins arranged in specific ways to fulfill their intended applications. The specific design and size of these parts are tailored to the application and load requirements.

The Impact of Materials on Hinge Parts Performance

The material from which hinge parts are manufactured plays a pivotal role in their overall performance, determining factors such as strength, durability, corrosion resistance, and cost. The selection of appropriate materials stands equally important to hinge type selection.

- Steel:Steel stands as a popular and economical material which manufacturers use to create various types of hinges. The material provides strong performance and durable characteristics, which makes it appropriate for different applications. Standard steel materials show high sensitivity to rust and corrosion when exposed to damp conditions or outdoor environments.

- Stainless Steel: Stainless steel alloys include chromium as an ingredient which enables them to resist rust and corrosion effectively. Stainless steel hinges excel in outdoor conditions and marine environments as well as spaces with elevated moisture content. The higher price point of stainless steel compared to standard steel becomes worthwhile because of its extended service life and dependable operation.

- Brass: Brass represents an alloy of copper and zinc which provides both visual attractiveness and strong resistance against corrosion. Brass hinges find their primary use in decorative settings and situations that need non-ferrous materials. They offer a classic look and are generally durable, although they might be softer than steel.

- Aluminum: Aluminum represents a strong lightweight material which demonstrates excellent corrosion resistance properties. Aluminum hinges find their primary use in weight-sensitive applications, including aircraft construction and specific door and panel installations. The material exhibits strong properties relative to its weight but cannot match steel when bearing heavy loads.

- Plastic: Plastic hinges serve lightweight applications that require maximum corrosion resistance and minimal strength requirements in containers and small doors found in humid environments. The range of plastic materials includes products with different resistance levels to wear and tear and different levels of flexibility.

The material selection determines how long and dependable a hinge will be. Stainless steel should be used for gate hinges exposed to outdoor conditions because it resists rust and provides long-lasting operation. Standard steel works well as a hinge material for interior cabinet doors.For purchasing these materials, you might need to login to a vendor’s platform.

How to Choose the Right Hinge Parts for Your Needs

Selecting the correct hinge parts involves considering several factors to ensure optimal performance and longevity.

- Application: The first step should be to determine the application of the system. The application determines whether you need to hang a door or window or cabinet or industrial equipment. The planned use of the object determines which hinge type will work best.

- Weight and Size Requirements: Next, evaluate the weight and size of the object you need to hinge. Heavier and larger items will necessitate stronger hinges with a greater load-bearing capacity to ensure proper function and safety.

- Frequency of Use: Consider the number of times the hinge will be used in your evaluation. High-traffic applications that require frequent door or cabinet use should use durable hinges, which might include ball-bearing features for smooth and extended functionality.

- Environmental Factors: The environment where the hinge will be installed requires evaluation. The hinge will face exposure to moisture along with chemical substances and extreme temperature conditions. The selection of corrosion-resistant materials depends heavily on environmental conditions that will affect product longevity.

- Aesthetics: Pay attention to appearance because of the desired look and finish matter. The selection of finishes includes polished brass, satin nickel and black which enables you to pair the hardware with surrounding elements for design cohesion.

- Budget:Budget considerations should be your final decision factor. The price of hinges depends on their type and material composition. Your performance needs must be balanced against your budget to discover the most valuable solution.

Here’s a practical guide summarizing suitable hinge types for various needs:

| Intended User/Application | Key Requirements | Recommended Hinge Types |

| DIY Homeowner (General Repairs) | Basic functionality, ease of installation, affordability | Butt Hinges (various sizes and finishes) |

| Cabinet Maker | Concealed appearance, smooth operation, adjustability | Concealed Hinges (cup hinges, pivot hinges) |

| Furniture Manufacturer (Mass Production) | Durability, consistent quality, cost-effectiveness | Butt Hinges (standard and heavy-duty), Piano Hinges (for specific designs) |

| Gate/Shed Builder | Strength, weather resistance, durability | Strap Hinges, T Hinges (steel or stainless steel) |

| Specialty (Jewelry Box) | Small size, discreet appearance | Barrel Hinges |

| Specialty (Piano Lid) | Continuous support, smooth movement | Piano Hinges |

| Removable Panels/Doors | Easy detachment and reattachment | Flag Hinges |

| Adjustable Lids/Screens | Ability to hold positions at various angles | Friction Hinges |

Step-by-Step Guide to Hinge Installation and Maintenance

Proper installation and regular maintenance are crucial for ensuring the smooth operation and longevity of your hinges. While specific steps may vary depending on the type of hinge, here are some general guidelines:

Installation:

- Mark the Position: Use a marker to indicate the exact spot for the hinge installation on each component of the fixed frame and moving object. The installation process requires correct alignment to achieve smooth movement.

- Create Pilot Holes:Drill holes through the marked screw positions before installation. The holes reduce wood splitting and simplify the process of inserting screws.

- Attach the First Leaf: Secure the first hinge leaf by using appropriate screws either on the frame or the object. Place the leaf flat against the surface with correct alignment.

- Align and Attach the Second Leaf: Secure the second leaf by placing it correctly next to the first leaf before fastening it to the opposing surface. Check the alignment to verify that the object moves freely and locks into position.

- Test the Movement: Open and close the hinged object to verify its smooth movement while checking for correct alignment. Make any necessary adjustments.

Maintenance:

- Lubrication: Regularly lubricate hinges, especially those in high-traffic areas or exposed to the elements. A few drops of penetrating oil or silicone spray can prevent squeaking and ensure smooth movement.

- Cleaning: Clean hinges periodically to remove dust, dirt, and debris that can hinder their operation. A dry cloth or a mild cleaning solution can be used.

- Inspection: Regularly inspect hinges for signs of wear, loose screws, or damage. Tighten any loose screws and replace damaged hinges promptly to prevent further issues.

By following these simple installation and maintenance tips, you can maximize the lifespan and performance of your hinge parts.

Troubleshooting Common Hinge Problems and Part Failures

Even with proper installation and maintenance, hinges can sometimes encounter problems. Understanding the common issues and their causes can help you troubleshoot and find effective solutions.

- Squeaking: The common hinge problem of squeaking occurs because of friction which results from insufficient lubrication or rust formation. The application of WD-40 or silicone spray to the pin and knuckles normally fixes this problem.

- Loose Hinges: The screws that maintain hinge leaves lose their tightness, which leads to door sagging and improper closure. The initial step involves screw tightening. Stripped screw holes require either longer or thicker screws together with wood glue and toothpicks to fill the holes or a slight relocation of the hinge.

- Rust and Corrosion: Hinges made from standard steel will develop rust and corrosion when they come into contact with moisture. A wire brush can be used to remove light rust and applying a rust inhibitor will help protect the surface. The most effective remedy for severe rust requires replacement of the hinge with stainless steel or another corrosion-resistant material. The pin serves as the initial component which displays rust symptoms.

- Stiff or Binding Hinges: The hinges become stiff because they lack lubrication or show signs of corrosion or experience misalignment. The first step involves applying lubrication to the hinge. Check for obstructions and inspect the hinge leaves and knuckles for damage when the problem continues. The adjustment of hinge leaves should be performed to correct misalignment.

- Broken or Bent Parts: Hinge parts such as pins and leaves become damaged when they experience both excessive force and wear. The replacement of the entire hinge becomes necessary in this situation. Check the maximum load capacity of the hinge to avoid these types of failures.

Quick action on these typical hinge problems stops additional damage while maintaining the operational state of doors and cabinets and other hinged items. The root cause of most problems leads to one particular component which requires maintenance or replacement.

Why Choose Maxave as Your Reliable Hinge Partner

The guide has explained how to choose appropriate hinge so you should work with Maxave as your expert supplier. Our main business activity focuses on delivering a wide range of premium furniture hardware products that include all hinge types presented in this guide. Our extensive production capabilities allow us to serve projects of all sizes which ensures your business receives dependable supply.

Our commitment to excellence is evident in our advanced manufacturing processes, such as our new-generation galvanizing line that significantly enhances the durability and anti-rust capabilities of our steel hinges. This focus on quality, combined with our stringent worry-free quality control measures, results in hinge you can trust for consistent performance.

Maxave recognizes the essential role that cost-effectiveness plays in every business operation. The MAX-VALUE model from our company provides superior value through optimized production processes and simplified supply chain operations. The optimized packaging we provide leads to reduced shipping expenses which directly benefits your business profits. Your business gains access to dependable hinge through Maxave because this company brings together more than ten years of experience with operations across the world.