Why Understanding Cabinet Parts Matters

Why immerse oneself into the particulars of cabinet construction? As far as this domain is concerned, knowledge is equal to money and fulfilment. Knowing the terminology such as face frame or drawer box construction lets you interface with designers, builders, and suppliers more productively. The chances of miscommunication are reduced and your vision is ensured to be realized more accurately.

Besides, knowing the constituent parts of a cabinet enables one to evaluatively judge its quality and practicality normatively. Why would a cabinet with solid wood dovetail drawers cost more than one with stapled particle-board drawer lids? Many of these insights inform one’s judgment when quotes are compared and significant investments made. If a hinge gives way or a shelf needs swapping out later, knowing which part of the cabinet they want to use is useful for easily accessing the replacement parts.

All these insights from basic understanding allow you to make decisions that fit choices perfectly aligned to one’s personal taste from a functional, aesthetic, and structural standpoint while still by budget limits. It goes without saying the kitchen becomes more than just a beautiful sight: it instead is durable and practical for years to come.

The Cabinet Box: Core Foundation

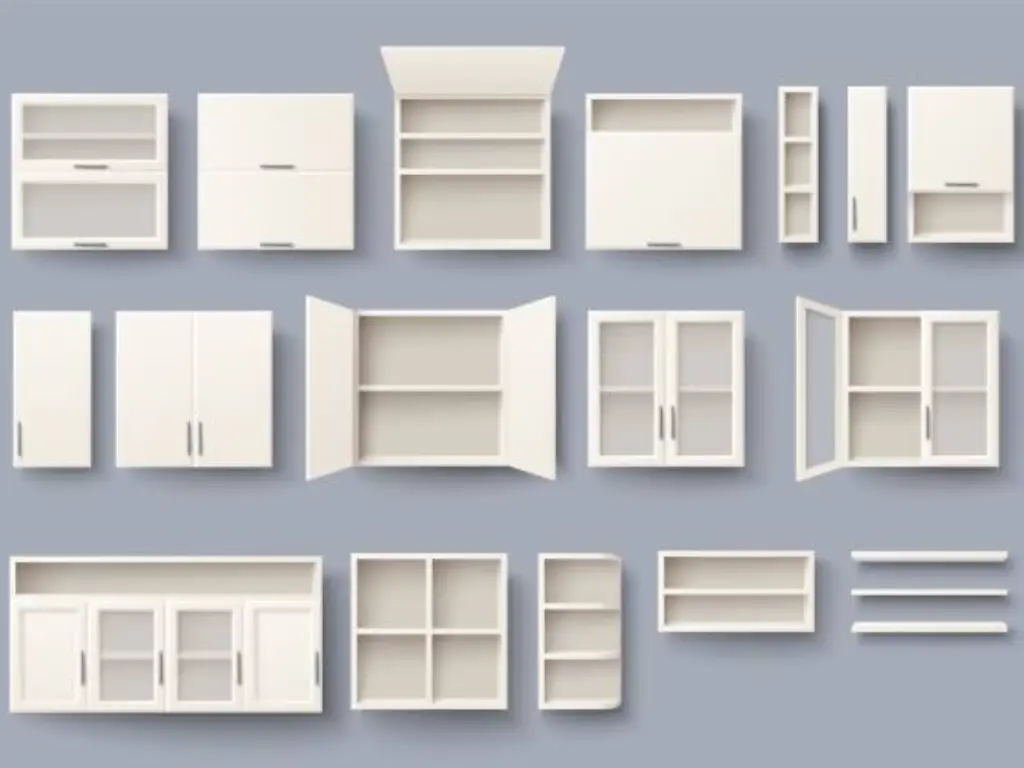

Every kitchen cabinet comprises its parts and these parts have specific names. The “cabinet box” or “carcass” refers to the base of the cabinet, from which everything else builds on, be it wall cabinets or base cabinets.

The cabinet box has two side panels, a top panel, and a bottom panel or floor along with a back panel. It is the core components that form the cabinet which determine durability, cost, and weight as a whole. Plywood, melamine, MDF, and particleboard with laminate finishes serve as common options. While the back panel may appear unimportant, it maintains the box’s rigidity. Without it, squareness would not be achievable when the cabinet is installed and throughout its lifetime.

From the perspective of construction, using thinner material for the back implies added rigidity and enduring sturdiness makes the borders squareness possible. Basic box construction is vital for smooth cabinet installation but becomes handy in discerning cabinet quality and design.

Framed vs. Frameless

Aside from the face frame, which is often neglected, there is an outline distinction in cabinet construction which is the difference between opening and attached face frame style. These two dominate styles are referred to as framed and frameless cabinet or European style.

Framed cabinets also come with a solid wood frame of around 1.5 to 2 inches, peripheral to the cabinet body, which serves the purpose of attaching front structural elements. The wooden cabinet cover known as face frame appears similar to a flat picture frame surrounding the cabinet aperture. Doors and drawers also can be and are usually placed upon this cabinet frame. This is a North American traditional design that increases strength as well as additional support to the box containing the cupboard. Also, they allow different aesthetic possibilities through different types (degree to which a door overlays the frame, including the top of the face frame) framing it termed door overlap).

Frameless cabinets, like their name suggests, eliminate the front frame. The cabinet box panels are thicker than usual to provide stability, and the edges are finished with edge banding. Specialized hinges and slides are used to mount the doors and drawers directly onto the cabinet sides. This type of construction allows for greater access as well as more space on the inside, since there is no frame lip blocking the opening. It allows for a clean, modern look with small gaps between doors and drawers. The decision whether to have framed or frameless cabinets affects the aesthetics, but also details concerning installation and hardware choices.

To clarify the distinctions:

| Feature | Framed Cabinets | Frameless Cabinets (European Style) |

| Construction | Box + Solid Wood Front Frame (Face Frame) | Box Only (Thicker Panels) |

| Door Mounting | On the Face Frame | Directly to Side Panels |

| Accessibility | Slightly Reduced by Frame Lip | Full Access to Interior Width |

| Appearance | Traditional; Various Overlay Options | Modern, Sleek; Minimal Gaps |

| Box Rigidity | Enhanced by Frame | Relies on Thicker Box Panels/Back |

| Origin | Traditional North American | European Origin |

Doors & Drawer Fronts: Defining Your Kitchen’s Style

If the cabinet box is the skeleton, the cabinet doors and drawer fronts are without a doubt the face and character of your kitchen. These elements are the most prominent and visible and determine the style of your kitchen, be it rustic farmhouse, sleek contemporary or timeless traditional. Classic white cabinets are a defined example of this. Styles of doors undergo greater variation but commonly include:

- Shaker: Characterized by simplicity. The cabinet door has a flat center panel surrounded by a frame (stiles and rails) with squarish edges. Versatility as well as popularity are its key traits.

- Slab: Its surfaces have no decoration, making it devoid of any recesses, frames, or outlines. Best with modern and minimalist designs, sometimes featuring glossy decorative finishes.

- Raised Panel: A center panel with a raised profile has a decorative routed edge where it meets the frame. A more traditional, formal look is created by using wood species such as cherry or maple.

- Recessed Panel: This style is like Shaker, but the center panel has some detailing and profiling instead of being flat.

Cabinet doors are (except for slab doors) defined by a frame of stiles (vertical sections) and rails (horizontal parts) that encase a center panel. The construction method of the cabinet components and else detail provided on the cabinet doors and the profiles utilized together form distinct styles of doors. As a rule, drawer fronts are styled to match the cabinet doors and can either be slab front or five-piece front styled to resemble Shaker or raised panel doors. Achieving a kitchen aesthetic still requires style choice to remain a top priority.

Inside Look: Shelving Systems and Drawer Boxes

The external design is given by the doors while the internal parts give structure and practical use in the long run.

Shelving Systems

The cabinet box’s edge has its borders filled with shelving which maximizes stored item visibility and access. Shelvess can either be rearranged or placed in predrilled holes. Structural support shall be given to enhance bearing capacity and reduce the risk of bowing under weight. Shelves’ materials most often align with the cabinet’s box made of plywood, MDF, or particleboard. Their thickness is critical if placed over prolonged spans. These do match the cabinet’s box- breather ports.

Cabinet’s drawer boxe

While often unnoticed, the quality of construction gives a good indication of the cabinets. The most affordable option is stapled particleboard, which is the weakest and most prone to wear. Better cabinets often have drawer box units made out of solid wood or stout plywood. Dovetail joints, which interlocks pins and tails in trapezoidal shape and connects them the sides of the drawer, is considered by many to be the crown jewel of all joints, testament to unparalleled craftsmanship strength. Other techniques are dowel joints or simply camera butt screws. The material and building method of the drawer box determines how well it maintains its shape amid stress and daily use over the years.

Finishing Touches: Molding, Toe Kicks, and Panels

Besides the primary features like boxes, doors, and drawers, additional finishing touches are made to complete the cabinet installation, achieving an aesthetic look for the space.

Molding (or moulding) has a dual purpose: it serves an aesthetic and practical purpose. The crown mold sits on top of the wall cabinets, specifically at the uppermost part of the cabinets, facilitating the transition to the ceiling. This crown mold adds a sophisticated element of architecture. Under-cabinet light fixtures are mounted concealed above upper cabinets and these light fittings are disguised using light rail molding. Sometimes, additional supporting or stylizing marks such as corbels may also be included for optional decorative purposes.

The base of the lower cabinetry has a recessed area which is also known as a toe kick. This particular design detail enables a user to position themselves closer to the countertop without the risk of stubbing their toes while standing. In addition to this the indentation enhances the ergonomics of the countertop. A toe kick is usually covered with a finished piece of material that matches the cabinetry.

An unfinished cabinet side on a simple box may look rough when it is at the end of a run. Skins or decorative end panels are used to cover the sides of cabinets that are otherwise exposed. These can be as simple as a thin veneer panel that matches the cabinet finish or more complex, thicker panels resembling a cabinet door that create a custom, high-end appearance.

Essential Hardware: Hinges, Slides, Pulls & Knobs

The hardware provides the first point of contact between the user and the cabinet. It governs the operation of the hinges, the smooth opening of the drawers, and the level of access available to the front of the cabinet. It also ensure that the cabinet works without difficulties.

The adjustable door hinges show a variety of brands that tend to fit the cabinet box frameless hinge or faceframe framed. Other types available are:

- European Hinges: They have concealed look. This offers a clean look along with incredibly high adjustability (up down, left right, in, out). The hume themselves are marvels of an engineered jaw.

- Traditional Butt Hinges: These are more conspicuous, utilized for a very stylish look.

- Specialty Hinges: For corner bi fold doors or other doors and specific utilization.

Slide bolts for drawers or glides bolt to the box capsule and the interior of the cabinet. This allows the drawer to be fully opened or closured. Other key types includes:

- Side mount Slides: They are visible when the Drawers is opened. Bolt with rollers which is rather basic and economically friendly.

- Under-Mount Slides: Usually placed under the drawer snug so they cannot be seen. These sorts of slides have much smoother processes and stronger weight limit. Beyond the nominally soft lack of sound mechanisms, many are equipped with the soft close controllers.

Pulls and knobs serve as handles which can be opened on cabinet doors and drawer fronts. They perform the function of opening the cabinet or drawer, but also serve an aesthetic role as decorative hardware. It is just like jewelry that can go on the cabinets. Craftsmanship of unparalled class are available in numerous finishes, styles and materials which work towards accenting entire kitchen design.

The Power of Premium Hardware: Elevate Your Cabinets

Going beyond basic accuracy, high-end hardware achieves remarkable results in performance and user satisfaction while expending the least amount of effort. The best cabinet doors utilize robust hinges that contain and prevent slamming soft-close hinges. These high-quality hinges also reduce noise and damage to the cabinet frame and door. They enable the gentle closure that prevents gaping, pinched fingers and whisper on door closure which guards noise silencing and a soft touch. And a kindly gentle facade masked with powerful closure.

Premium drawer slides and soft-close under-mounts guarantee noiseless gliding of drawers and even the most demanding load won’t change that fact.

Primary decorative hardware including pulls and knobs are crafted from solid bearing and easily damaged masked finishes that don withstand tarnishing, chipping, or breaking. Even though the best hardware rings the cash register first on purchase, easiest operation, engineering, and prolonged use provide absolute better long-term benefits; and most importantly calm and anguish, ensuring finely-tuned cabinetry hot and cold soft setting and undeviating smooth functioning uninterrupted for years of silence.

Maxave: Your Partner for Quality Hardware Solutions

For this reason, people who are investing in their cabinetry to ensure that they have the most top performing and longest lasting furniture hardware must choose a dedicated furniture hardware specialist.

Furniture hardware manufacturers like Maxave (https://www.maxavegroup.com/) only deal with engineering and manufacturing of high quality hardware solutions. In addition to this, they possess a diverse portfolio of extraordinarily tailored hinges, (soft close options in place), sturdier drawer slides crafted for hassle free and weight bearing operations, and luxury collection of lovely and sturdy pulls and knobs.

When choosing the components from a trusted source like Maxave, you are investing in reliability, functionality and the pinnacle of cabinetry presence. Quality is their priority, so these crucial functional elements help offer, not take away from the kitchen investment as a whole.

Conclusion

Understanding the parts of a cabinet make it easy to navigate a kitchen cupboard, in particular: the box, doors, drawer fronts, shelves, the cabinet’s frame, and even the hinges. All have an impact on a kitchen’s standards of aesthetic and practicality, while also determining its structural strength and durability. Balance between the adornment and functionality of a frame are reflected in the material that serves as the finishing touch— white wood, veneer and melamine to name a few.

Knowing such attributes aids a person who is designing a kitchen psychologically embellish a design that is unique to them and select the cabinetry that best meets the space’s needs. Understanding these factors guides one to a kitchen that looks good, is sturdy enough to stand the test of time, and will not make a person regret their choice later down the line.