Have you ever felt confused when you went to a DIY store? You might be wondering which one of the many screws you will be seeing. There are many types, sizes, and materials, some of which are light, medium, heavy, and extra-heavy. Each one of them looks like it was made especially for your project. However, the decision may be tough. We’ll investigate the sizes of screws to find the answer to this riddle. This guide will enable you to understand the use of screws. As you have learned, your next project will be done in an organized way, not based on guesswork.

Overview of Screw Sizes

It is often confusing to get to know what the screw sizes are. They have their code that is formed from numbers, letters, and terms. This can thus be frustrating even to those who are committed to do-it-yourself projects.But don’t worry. Your guide will tell you everything about screw sizes that you need to know. At their heart, screw sizes are about two things: diameters and length. The kind of gloves you need depends on the material and what the job is. You could go for a wood screw if it is for wood or a masonry screw when it is dealing with concrete.

However, it is not only about choosing a long screw but also about the additional factors. It is the diameter that is the most critical factor. It will be too small and weak to hold well. The danger of the size is that you can easily hurt your wood piece. Use of a screw size chart is very useful at this point. It helps you either screw or unscrew the item. Whether you are analyzing a chart or the smooth part of the screw shank, these sizes will always be helpful in your planning.

Explanation for Inch and Metric Screw Sizes

There are two main ways to measure screws: millimeters and metric. In the USA, inches are prevalent. You may encounter something similar to a “#8 screw.” It means the screw is #8 in size, that is the diameter and length. The remainder of the world use the metric system. Here, you have to measure the screws in millimeters (mm) only. This is important in case the project requires exact dimensions.

Switching between inches and meters is not a problem. You can do it in a way that is simple with a formula or a chart. This applies if you are using a plan from another country. It is the tool that makes the difference between a screw that fits well and one that doesn’t. With a bit of knowledge and a few tools, you’ll be OK.

The following diagram will facilitate you in comparing inch screw sizes to metric ones. This is great when you need to switch between the two systems. Perhaps you are using instructions that give you the imperial measurement units, or you need screws that are measured in metric.

Inch and Metric Screw Sizes Chart

| Inch Size (Diameter) | Metric Equivalent (Diameter) |

| #0 | 1.6mm |

| #1 | 1.8mm |

| #2 | 2.2mm |

| #3 | 2.5mm |

| #4 | 2.8mm |

| #5 | 3.1mm |

| #6 | 3.5mm |

| #8 | 4.2mm |

| #10 | 5.0mm |

| #12 | 5.5mm |

| 1/4″ | 6.3mm |

| 5/16″ | 8.0mm |

| 3/8″ | 9.5mm |

| 7/16″ | 11mm |

| 1/2″ | 12.7mm |

| 5/8″ | 15.8mm |

| 3/4″ | 19.0mm |

| 7/8″ | 22.2mm |

| 1″ | 25.4mm |

Additional Measurement Conversions for Context:

| Conversion Example | Inch to Metric | Metric to Inch |

| Diameter Conversion | 1/4″ to mm = 6.3mm | 5mm to inches ≈ 0.197″ (Closest to #10) |

| Length Conversion | 1″ to mm = 25.4mm | 50mm to inches ≈ 1.969″ (Just under 2″) |

I have found this chart to be very helpful for my detailed projects. It is also important when you are trying to fit the screws to parts made with different systems. Sometimes information is in one system. This chart is a way to visualize them in a more meaningful way.

Keep in mind, that this graph only emphasizes the thickness of screws. If you convert lengths, you will do it in a similar manner. However, the lengths are most often given in mm or inches as the direct units. At times, you might be required to use the nearest size in rounding. The reason is that the exact fit does not always exist. Screws in metric and inch systems are marked differently.

Be sure to look through the specific sizes. Pay special attention to the pitch and length of the threads. These features are very crucial for the screw to do the job perfectly in your project.

Screw Size Chart: A Handy Reference

Selecting screws by specifications may be a little complicated. With this help, I am attaching here a concise and practical chart. The sizes of screws, their thickness, length and typical applications are the things this handout deals with. This chart is to help you choose the right kind of screw for jobs of different types.

| Screw Size | Diameter (Metric) | Decimal Inch (Inch Decimal) | Metric Equivalent (mm) | Thread Pitch (TPI, UNC Standard) | Length (Metric) | Common Applications |

| # 0 | 1.6mm | 0.06 “ | 1.6mm | 80 | 1/8 ” -1 ” ( 3-25mm ) | Small hobby projects , electronics |

| # 1 | 1.8mm | 0.073 “ | 1.85mm | 72 | 1/8 ” -1 ” ( 3-25mm ) | Delicate woodworking , glasses repair |

| # 2 | 2.2mm | 0.086 “ | 2.18mm | 64 | 1/8 ” -2 ” ( 3-50mm ) | Toy assembly , small electronic devices |

| # 3 | 2.5mm | 0.099 “ | 2.51mm | 56 | 1/4 ” -2 ” ( 6-50mm ) | Thin metal joining , precision woodworking |

| # 4 | 2.8mm | 0.112 “ | 2.84mm | 48 | 1/4 ” -2 ” ( 6-50mm ) | Light – duty woodworking , trim , and cabinetry |

| # 6 | 3.5mm | 0.138 “ | 3.51mm | 32 | 1/4 ” -3 ” ( 6-75mm ) | General construction , furniture , outdoor projects |

| # 8 | 4.2mm | 0.164 “ | 4.17mm | 32 | 1/4 ” -4 ” ( 6-100mm ) | Structural woodworking , decks , framing |

| # 10 | 5.0mm | 0.190 “ | 4.83mm | 24 | 1/2 ” -5 ” ( 12-125mm ) | Cabinetry , heavier construction tasks |

| # 12 | 5.50mm | 0.216 “ | 5.49mm | 24 | 1/2 ” -6 ” ( 12-150mm ) | Heavy – duty construction , landscaping |

| 1/4 “ | 6.3mm | 0.250 “ | 6.35mm | 20 | 1/2 ” -6 ” ( 12-150mm ) | Machinery , automotive parts , structural steel |

| 5/16 “ | 8.0mm | 0.313 “ | 7.94mm | 18 | 3/4 ” -6 ” ( 20-150mm ) | Heavy engineering , construction , marine applications |

| 3/8 “ | 9.5mm | 0.375 “ | 9.53mm | 16 | 3/4 ” -6 ” ( 20-150mm ) | Construction , heavy machinery , bridges |

| 7/16 “ | 11mm | 0.438 “ | 11.13mm | 14 | 1 ” -6 ” ( 25-150mm ) | Large structural connections , industrial applications |

| 1/2 “ | 12.7mm | 0.500 “ | 12.7mm | 13 | 1-6 ( 25-150mm ) | Structural steel , large machinery , automotive |

Key Points to Remember:

- Diameter (Metric): It means the thickness of the screw and this has a direct effect on the drill bit size that is needed for a pilot hole.

- Length (Metric): Specifies the length of the screw, which is very important for passing through the depth of the materials being connected without affecting the structural quality.

- Common Applications: Provides a general idea about the location of the different screw sized usually used, but the actual use may vary depending on the specific project requirements. In addition to the graph, you should consider whether the screw is made of material like stainless steel or brass and whether the head is shaped like a flat or Phillips. This is important because it determines the efficiency of the screw operation, especially with different materials or in different weather conditions. This diagram was created for you to make the right choice of screws for your project to be done strongly and beautifully. This chart is the most basic tool in the kit that can help you to get screws without much effort. With the right screw size, you can use this screw to add the feature to your project, as well as ensure your result is both safe and attractive. The chart below is just an example to illustrate the basic plan; your particular project may require some adjustments. If the job is very specific or if it’s about construction or hardware, it’s better to consult a specialist.

Types of Screws and Corresponding Size Considerations

The difference between the right and wrong screws can be crucial for your project, so learning how to choose them is essential. The different screws are used for specific tasks and materials. Let’s break down some common types of screws, their sizes, and when to use them:Let’s break down some common types of screws, their sizes, and when to use them:

| Screw Type | Size Range | Common Sizes | Application Scenarios |

| Wood Screws | #0 to #24 | #8 | General woodworking, attaching pieces of wood. Coarse threads for softwood, finer threads for hardwood. |

| Sheet Metal Screws | #0 to #14 | #6 to #10 | Fastening metal sheets, with finer threads for thin metal and self-drilling tips for thicker metal. |

| Masonry Screws | 1/4″ to 1/2″ diameter | 1/4″ by 3″ | Anchoring into concrete, brick, or mortar for medium to heavy-duty tasks. |

| Deck Screws | #6 to #14 | #8, #10 | Outdoor decking, resistant to corrosion, with length depending on material thickness and environmental conditions. |

- Wood Screws: These screws are popular for wood projects, as they have sharp points and deep threads. For softwoods, we recommend using screws with wider threads in order to prevent the wood from splitting. For the hardwoods, you might want threads to be thinner for them to go in smoothly without pre-drilling. However, for the most durable woods, you will still need to drill a small pilot hole for the screw. Many wood screws are #8 in size, which is a common size for a variety of wood work.

- Sheet Metal Screws: These screws have sharp threads with a threading design that is capable of cutting metal. In case you’re working with thin metal, the screws should have a narrower thread to prevent the metal from bending. When you need to fix metal that is thicker than normal, self-drilling screws are a good option because they make the job easier. Sizes, including #6 to #10, are adaptable and are perfect for various metal thicknesses.

- Masonry Screws: These screws are made for concrete, brick, or mortar. Having the right size and thickness is a key component of masonry work which enables a good grip. Longer screws are better for heavy-duty anchoring, but with brittle materials one should be cautious not to crack. The usual dimensions for these screws are 1/4 inch by 3 inches, which meet most masonry needs.

- Deck Screws: Developed specifically for outdoor work, these screws have a hard finish to prevent them from rusting. On the size question, take into account the thickness of the deck material and the climate in your area. Longer screws are preferable in wet or varying climates where wood swells or shrinks in size, but they do not loosen up. The standard sizes for deck projects are #8 and #10. These two sizes offer a good balance between strength and appearance.

In brief, the choice of the proper screw is the matter of matching the material you work with and the target you pursue. Regardless of whether it’s wood, metal, masonry or just outdoor projects, there is a screw size and type that is just perfect for that task.

How to Choose the Right Screw Length?

The right screw length is not only an item that should be selected with the purpose of ensuring the project’s durability but also one that should be chosen for the sake of the project’s beauty. Here’s how you can determine the most appropriate length for your screws:Here’s how you can determine the most appropriate length for your screws:

1. Start with Material Thickness: The first step is to measure the overall thickness of the materials that you wish to bond with. This measurement is paramount because it provides a foundation for you to determine the screw length that suits you.

2. Apply the Halfway Rule: Sufficient bite for the screw to penetrate the lower material’s thickness at least half-way is required for the best grip. A screw should be inserted through the hole on the opposite side of the marked line to prevent it from protruding, thus providing a neat finish. The ideal screw for such a material with a total thickness of 2 inches is one that extends at least 1 inch into the bottom material.

3. Consider the Type of Screw Head: The head type of screw, such as flat, pan, or countersunk, determines the way in which you measure the screw length. If the length of screws with a countersunk head is measured, then the head length is included because the head is flush with the surface. Unlike the screws with a larger head or the screws that do not sit flush, you need to measure the length from the bottom of the head to the tip of the screw.

4. Adjust Based on Application: Adjust the length of your screws depending on your project’s particular demands. In areas of heavy loads or where the materials are likely to split, small adjustments to the screw length may be required to achieve the maximum grip strength without damaging the material.

Through an accurate selection of the right screw length, considering the largest diameter of the screw for the material thickness, and tailoring the screws for different ways of use, you will achieve a secure and neat result. Regardless of the size of the project, from a simple repair to a complex construction, these tips will help you to reach a successful completion of the whole project.

How to Measure Screw Sizes?

In order to ensure the success of your projects, it is important to measure the correct screw sizes correctly. Here’s how to accurately measure screw dimensions:

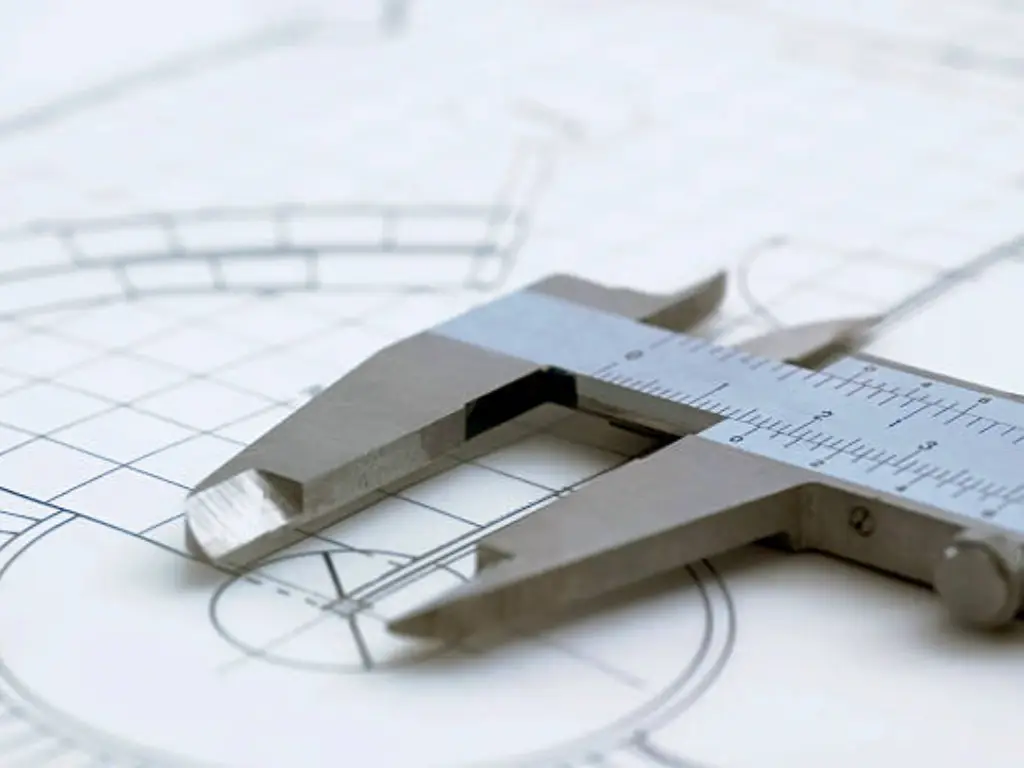

- Measuring Width (Diameter): Make use of the caliper to measure the screw’s diameter. This instrument allows for exact measurements of the screw’s threads, which are the parts of the screw that are the thickest. It is effortless. You just need to place the caliper around the thread, and measure the biggest area. Then, read the measurement. And for the screws with a flat head, the procedure of measurement remains the same, by observing the thread width.

- Measuring Length: The methods for length measurement are dependent on the screw head type. Measure from the bottom of the head to the end of the screw as a rule. Nevertheless, for flat head screws, also consider the head when you are measuring since it is placed in the same level with the material’s surface. It is better to use a ruler or a caliper for this purpose. Refer the tool’s zero mark with the head’s bottom (or top for flat heads) to obtain the accurate length.

- Optional – Measuring Thread Pitch: The next step is for machine screws. Thread pitch is the distance between threads, while thread count is the number of threads per inch. To measure this, use a thread gauge and place the gauge’s threads next to the screw’s threads until you find the perfect fit. This dimension helps in choosing compatible nuts or it can be used to make accurate engagements in the project.

Having a couple of calipers, rulers, and thread gauge at your disposal will enable you to take on different projects without any hassle. Keep in mind that, accurate measurements will make the product stronger and will give a reliable result. Be careful and precise to avoid any problems.

Choosing Critical Factors of Thread Pitch and Diameter

Thread pitch, and screw diameter are essential when it comes to screw selection. We can determine how thick the screw is by looking at its diameter. This influences how tight the screw is and how well it manages to fit in various materials. The Thread pitch (Thread Pitch) is the distance between the threads. Insuring that the screw holds well in the material is also very crucial.

- Coarse Threads: It is more effective on soft materials such as wood. They generally hold tightly and are least likely to tear the material.

- Fine Threads: These work well with hard materials. They have more threads that touch the material, making a tighter hold.

It is important to carefully select the appropriate screw thread dimension (thread pitch and diameter) for the job. It is the one which gives your project durability and sustenance.

Material Matters: How Screw Size Affects Material Integrity

Sizing your screws is an important part of the process.. In the case of a screw being too large, it may cause wood to split or metal to bend. If it is too small, it will not help a lot in holding things together.

- For Wood: In this case, softwoods require larger diameter screws to prevent the pull-through phenomenon. The best hardwoods are the ones with a smaller thread to avoid splitting.

- For Metal: There is the need for fine-threaded screws for thin metal sheets. The larger diameter of the metal may require stronger machine screws.

Selecting the right screw size is an important detail to ensure your project is firmly fixed. And, I think the environment is also an important factor. For exterior projects, stainless steel screws protect against rusting. For concrete or masonry, special screws are designed to be screwed in without any damage. Every time I pick the correct screw size, taking both the fit and the future impacts of the material into account.

Avoiding Common Mistakes in Choosing Screw Sizes

Surely, we have all been in a hardware store at some point, and we have looked at the fasteners wondering which is the right size. When you make the wrong decision it is easy to do so and you can make mistakes as a result. Here are some errors to avoid:

- Thinking Bigger is Always Better: The screw which is too big might look strong, but it can be very harmful to your material. Likewise, it can split wood or be too brittle for the material to bend.

- Using a “One-Size-Fits-All” Approach: One can easily make mistakes when one unthinkingly chooses a screw size without considering the material and the task. The different tasks and stuff require different screws.

- Skipping Pilot Holes: Not drilling pilot holes, as it is the case with hard materials and large screws, is a common mistake. The pilot hole will make the screw insertion easier and help to avoid the material splitting.

- Ignoring Special Screw Types: Just like when you do not take into account the type of screw that some materials need, like masonry screws for concrete or lag screws for heavy loads, you will just weaken your project.

It is important to note that the purpose of selecting the right screw size is not just to get the biggest one. The whole thing is about the choice of material, the choice of the job and the making of preparations. If you can learn from these common errors, then your projects will be more successful and long-lived.

Practical Applications of Screw Size Selection

Now, let us use what we have learned about the sizes of screws to real-life applications. For example, if you are constructing a deck in the outdoors, you will need the screws with durability, such as the stainless steel deck screws. These are the pieces that help to hold the heavy loads and also resist severe weather. For a drywall installation, you would need to use drywall screws instead. These are the ones that are crafted for holding the drywall in place without a single scratch.

More Than A Furniture Hardware Manufacturer

Your Sales Growth Specialist

These principles are not limited to big projects alone. It is about more than just the big stuff like cars and machines. It is about hobbies and smaller tasks too, such as model car building and fixing gadgets. The screws that are tiny and often drop appear to be simple and easily replaceable but they have their own sizes and threads. They are perfectly designed for doing those tasks. Using the best size in your project will ensure it will be strong. If the screw is too big or too small, it might create a situation where things are not fitting right or not staying together.

Remember that the strength and size of the screw should be matched to the job which will be done. The screw size you need is determined by the material of your project, its weight, and the environmental conditions it will be exposed to. Selecting the appropriate screw size guarantees the quality of your accomplishments, as well as a successful completion of your projects. It may be a simple repair or a major rebuild, but the right screw size selection is important for the success of the project.

Conclusion

At first, understanding screw sizes might seem overwhelming. However, with a little bit of knowledge and the correct tools such as the screw size chart and a digital caliper, it can be less difficult. Whether it’s deck screws for outdoors or machine screws for indoors, you’ll find the appropriate one.

The next time you’re in a hardware store, take this guide with you. Be aware of the kind of materials to use, the weight they’ll hold, the prevailing weather and even possible mistakes. With the right screw size, your projects will be more than just sturdy. They’ll show the skill of a true craftsman. Happy building!