Introduction

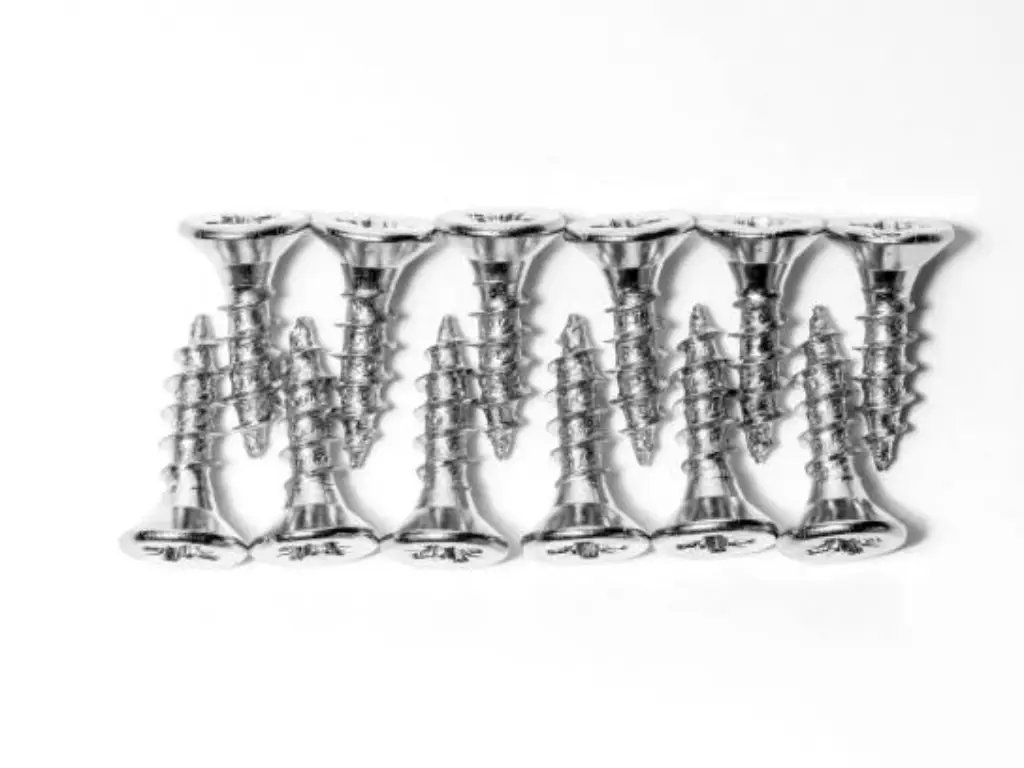

In modern construction and assembly lines, self tapping screws play a crucial role because they make it easier to join materials without pre-drilled holes. Self tapping screws are so helpful because they form their own thread as they are screwed into the material, whether it is metal, plastic or wood. This in turn makes the installation process faster while at the same time improving the assembly’s structural stability. Consequently, these types of fasteners are invaluable when it comes to things like securing metal roofing or mounting plastic housings and that is why self tapping screws are a major aspect of any discourse about building and fastener installation.

When talking about what self-tapping screws actually mean we cannot ignore various parts that make up these fasteners though. These include but not limited to gimlet point which is an alternative name for a sharp point on each screw meant to pierce through the material thereby eradicating the need for any pilot hole. The different threads have widely differing patterns with designs tailored towards specific materials or uses hence demonstrating how adaptable they can be serving various purposes effectively.

Key Features of Self Tapping Screws

| Feature | Description | Advantage |

| Sharp Edge | Capable of creating its own hole in the material, ensuring a tight and secure fit. | Eliminates the need for pre-drilled holes, reducing installation time. |

| Head Types | Available in various forms such as flat, round, and pan to suit different finishing needs and accessibility requirements. | Provides flexibility in applications, ensuring optimal finishing and installation. |

| Material | Often made from stainless steel or coated metals, offering durability and resistance to corrosion. | Suitable for heavy-duty applications in adverse conditions without deteriorating. |

| Threaded Shank | Designed to secure firmly even in thin sheet metals or plastic housings. | Ensures a secure hold in various materials, increasing reliability. |

| Sharp Tips | Comes with either pointed ends or flat points to minimize material damage and enhance structural integrity. | Tailored for specific applications to reduce damage and improve performance. |

Self-tapping screws are famous for their sharp edge, which taps into the material with painstaking care, creating its own hole and establishing a strong connection. The screws come along with different types of heads including flat, round and pan that are chosen according to requirement for finishing and the accessibility of the screw head. Furthermore, when it comes to heavy duty applications in adverse conditions, materials like stainless steel or coated metals are commonly employed in manufacturing these self tapping screws because they are durable enough as well as resist corrosion.

In addition to that fact, these screws have also got a threaded shank meant for securing them even on thin sheet metals or plastic housings. Further enhancing the effectiveness of self tapping screws is their varying shape sharp tips which have either pointed end or flat points depending on what role they play. This variety ensures that damage to materials is minimized hence increased overall structural integrity by ensuring that each specific application utilizes appropriate screw.

Types of Self Tapping Screws & Uses

Thread Forming Screws: These are perfect for soft metals like aluminum and brass. They work by displacing the material around the screw, providing a secure fit without removing any material. This type of screw is excellent for applications where material integrity must be maintained.

Thread Cutting Screws: Equipped with a cutting edge, these screws are used primarily in harder materials, such as stainless steel or iron. They remove a small amount of material to form a mating thread, ensuring a strong hold in thicker and denser substrates.

There are several types of self-tapping screws which serve different purposes. The widely known ones include thread forming and thread cutting screws. Thread forming screws often used in softer metals like aluminum push aside the material without taking it out to make a fastener that is snug and tight. On the other hand, thread cutting ones have sharp edges that cut materials giving rise to threads making them appropriate for thicker gauge metals and guaranteeing strong fastening.

Self tapping screws perform a wide variety of functions. They can be found practically anywhere from HVAC systems through metal brackets to even automotive assembly plants. Specific tip shape and thread designs on each kind of screw ensure improved performance by reducing stress on materials during installation process hence ensuring durability and long life span for joined pieces.

Self Tapping vs. Self Drilling Screws

Self Tapping Screws

Self Tapping Screws are designed to tap their own thread in a hole that has been pre-drilled into material, making them perfect where there is need for precision. The screws usually have a sharp pointed end that pierces through the material, enabling the screw to make its own thread without removing unnecessary parts of it. In this regard, they can be used in non-metal and metal applications which require maintaining the integrity of the material.

Self Drilling Screws

They are also known as Tek screws, and they are characterized by having a drilling bit at one end. This peculiar design enables them drill holes and create threads within the bits in one process, hence reducing time taken during fixing or installation. Self drilling screws find main application in large-scale construction schemes involving such materials as heavy gauge steel and metals.

Key Differences and Applications

- Pilot Hole Requirement: In most cases, self-tapping screws require pilot holes especially in thicker and harder materials which may add an extra step on the process of installation. This is a major advantage for large-scale construction projects since they can drill their own pilot hole.

- Material Suitability: They however are highly effective with compact materials including steel and hard metals where it would be difficult to make a manual pilot hole. Self-drilling screws will prove efficient in such case.

- Installation Efficiency: When time and labor costs are critical factors, metal building or steel framing projects will benefit from faster installation through self drilling screws.

- Usage Scenarios: For instance, the electronic assemblies that should have minimal damage to material would make use of self-tapping screw as their preferred choice. However, the commercial building exteriors that require robust performance in structural tasks need self-drilling screws that give fast throughput and strong holds.

Knowing these distinctions is important when picking out a screw for your work which will ensure reliable and long-lasting assemblage, while also improving work output. The ideal type of screw can make a big difference to the success and quality of a building project whether it is the versatility of self tapping screws, self drilling screws, or other types of screws in fragile installations or the strong time saving characteristics of self drilling screws in harsh environments.

How to Use Self Tapping Screws

When it comes to using self-tapping screws properly, getting their effectiveness and preventing damage to either the screw or the material depend solely on how well they are used. First, determine which type and size of screw suits your application best. It is advised that one should consider factors such as length of screw, thickness of the material and type of material. One frequent error is utilizing an inappropriate size screw; this can lead to hole stripping or inability to effectively attach materials together.

For you to be able to install a self tapping screw, there is need that align the screw with the material where it is supposed to be put. When working with harder materials, a small pilot hole can help guide the screw and reduce chances of misaligning it. The use of suitable screwdriver or power drill will enable you insert the screw and ensure constant pressure and speed are applied so that overheating and damage of material by the screw does not happen. Right installation is able to guarantee both firm hold as well lengthened makings for both; materials as well as screws’ life span.

Applications of Self Tapping Screws

There are a lot of versatile, reliable self-tapping screws used in different applications and sectors. They are commonly found in the building industry for metal roofing and framing where they make it possible to have quick, safe and resilient assemblies. Self-tapping screws that secure metal-to-metal or metal-to-other materials without pre-drilled holes are indispensable for instance while putting up metal buildings or roof sheets where fast assembly is necessary.

Also, these screws are applied extensively in DIY projects by homeowners, vehicle repairs and even assembling electronic gadgets with demand for accurate results and firmness. Such reasons as availability to all kinds of materials by self tapping screws and user friendliness have made them quite popular among professional builders as well as just enthusiasts who do things with their own hands.

Avoiding Common Self Tapping Screw Mistakes

To avoid self tapping screws from going wrong, it is important to know the requirements specific to the project at hand. Poor performance and potential failure can be caused by picking out a screw with the wrong size, type or even length. Also consider that the drill bit used must be slightly smaller than the screw itself so that its thread grip remains intact. Moreover, any excess force applied to driving this screw breaks it off or strips it down especially when made of brittle materials.

In addition to these considerations, we have to put in mind what kind of environment they are being used in. For example, using standard steel screws without proper coating in moist prone environment can cause corrosion and weaken the grip over time. On top of that, one may go for coated or stainless steel self tapping screws that can reduce such problems hence extending both screws as well as assembled structures life expectancy.

Maintenance & Troubleshooting Tips

Regular examinations are very important to ensure that self-tapping screws remain intact. Environmental conditions such as fluctuating temperatures and humidity can cause material expansion or contraction which may lead to loose screws over time. To maintain the structural stability of a product, screws should be checked and retightened periodically. The connections will still be tight, and besides that, it elongates the lifetime of a joint.

Common issues with self tapping screws include difficulty driving the screws into material or screws that fail to hold securely. Here are some steps to resolve these problems:

- Compatibility Check: Make sure that you use the right kind of self-tapping screw for your material. Using wrong class of screw might cause poor performance of the material failure to hold it properly.

- Damage Inspection: Look at each screw for any signs of damage or wear. Once a screw is damaged or worn out, creating or maintaining a thread becomes hard hence making it difficult to drive into any other material.

- Replace Faulty Screws:when a screw is stripped or breakage occurs; an immediate replacement should be done without hesitation as allowing a compromised one may compromise integrity causing more damages or safety concern during operation.

By considering regular maintenance and troubleshooting guidelines provided above, you can increase the efficiency and durability of self-tapping screws in any project. Proper care on a regular basis along with observance for recommended applications will not only prevent typical failures but also keep your installations strong over time.

Conclusion

In a wide range of construction and assembly applications, self-tapping screws play an important part. To enhance the success of any project, it is important to have knowledge on their types, uses and common mistakes. Choosing the correct screw for the task and using it properly will give a secure hold that will last under every circumstance. The capabilities and application areas of self tapping screws will continue to be improved as technology becomes more advanced and new materials are introduced in the industries hence making them indispensable in manufacturing firms as well as in construction.

Discover Maxave Excellence

More Than A Furniture Hardware Manufacturer

Your Sales Growth Specialist

Enhance your furniture projects with Maxave, your trusted partner in superior furniture hardware solutions. Visit our website to explore our innovative products and find out how we can help elevate your designs with quality and style.